- With over 35 years of industry experience and a team of 43 dedicated professionals, MAPLAST CZ combines precision, reliability, and flexibility to deliver comprehensive advanced plastic solutions tailored to customer needs.

- We are based in strategic location in the heart of Europe, in Brno–Přízřenice, Czech Republic.

- Total facility area: 7 500 m²

- Quality focus

The high-quality standards (we are certified for ISO 9001:2016 and ISO 14001:2016, MODULE D PED certification from TÜV and others) make MAPLAST the right partner for all highly demanding customers. - High flexibility

Thanks to outstanding project management, expert team and lean production we are able to secure for you small to large scale production at the most competitive price. - Customer focus

You tell us what you need, and we will go the extra mile for you at every stage. Our prime goal is offering clients added value to support their success. - Over 35-years of experience in demanding segments

We have successfully provided comprehensive services to companies from the electrical, water management, medical, food packaging and telecommunications industries for over 35 years.

Besides traditional focus on Central and Western Europe incl.UK, we are also effectively exporting goods to North America and middle East(e.g.Turkey) and Nort Africa(e.g.Egypt).

Our activities

Injection Moulding

Our modern production floor equipped by 28 high-precision injection moulding machines (brands: KraussMaffei and Demag) with clamping force ranging from 35 to 1000tons is allowing us to manufacture wide range of mouldings from 0,5g to 3500g. The high efficiency is supported by appropriate peripherals and robotization.

We are successfully processing all thermoplastics including commodities (PP,PE,PS,ABS,PVC), engineering plastics like PA6,PA66,PC/ABS,TPE incl. variety of materials filled with Glass Fibers, Carbon Fibers or Minerals. We are skilled in processing high performance materials such as PEEK,PEI,PSU etc. We are also well- experienced in processing PCR and PIR recyklates.

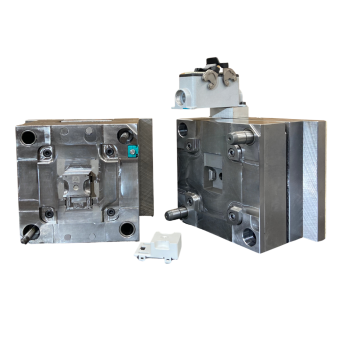

Tool shop

Our in-house tool shop allows us to efficiently conduct any needed repairs or mould adjustments without any production delay. In case of production relocation to our site, our tool shop has the expertise to repair even heavily worn moulds, extending their lifespan.

Assembly

We are providing options for simple or highly advanced assembly completion

We can combine different components into a single product according to your needs.